What goes into the production of a bag of fertiliser?

Related Articles

Andrew MacMahon, Fertilizer Product Manager at Rigby Taylor, explains that understanding how raw materials work can lead to greenkeepers making the right choice

Professional turf managers of today have available a multitude of fertilisers and analysis that can meet every situation. Such a range of options however can make the selection very difficult – there a number of factors that need to be considered that will assist the decision-making process.

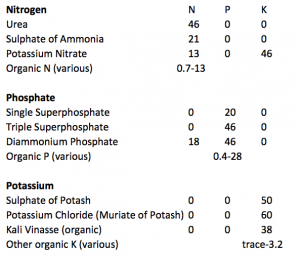

In fertiliser manufacturing, there are several sources of raw materials used to reach the required analysis. Below are listed some of the typical nutrient sources used in fertiliser production, with their respective analyses:

When selecting a granular fertiliser, the choice will be either a compound (homogenous) or a blend.

Compounds: A compound fertiliser contains all the declared nutrients in each granule and all the granules will predominantly be the same colour.

For example in a bag of 14-2-10 + 3.3MgO, each single granule will contain all four nutrients. These granules may also contain a combination of other additives such as humates, lignite, zeolite, sand, anti-caking agents (to stop the granules sticking together), anti-dust agents, root enhancers, bio-stimulants, wetting agents or herbicides. These additives may either be added as part of the granule forming process or sprayed on after the granule has been formed.

Fertiliser granule production

Producing a quality compound fertiliser involves numerous processes and relies heavily on the experience of the manufacturer who will know and understand the process.

Blends: A fertiliser blend is not manufactured in the same way as a compound fertiliser. A blend is a mix of nutrients and again as an example, in a bag of 14-2-10 + 3.3MgO, each single granule will only contain a single nutrient such as nitrogen (N) or phosphate (P) or potash (K) or iron (Fe). As with compound fertilisers, blends will contain some and this can be sand in the finer mixes, or limestone grit in the coarser products. There can be in excess of 50 per cent filler in some blended fertilisers, which means that more than half the granules and therefore half the bag has no nutritional value. The individual granules will be different colours as the raw materials are all colours. A blend will not have any sprayed-on additives.

There are three types of blended fertilisers.

Type 1 blend is where all the different granules are similar shapes and sizes.

Type 2 blend is where all the nutrient sources are different shapes and sizes.

Type 3 is a blend of coated products with compound granules.

This type 3 will be more expensive and the granules should be very uniform in size to optimise application accuracy. They will contain two to four different granules, depending on the number of the coated sources of nutrient.

Producing a blend, is a much simpler process than for compounds, and in fact it can be carried out by anyone who has access to the raw materials and a mixing container.

Depending on the analysis of a fertiliser there might be numerous sources of each nutrient, which provide the benefit of different release patterns.

The Apex Organic range of compound fertilisers has up to 11 different ingredients with up to four sources of nitrogen, both mineral and organic. The Premier HG range, which is also a compound, has 12 to 17 different raw materials.

There can also be several sources of the same nutrient in a blend as well. This means that when applying a blend, the nutrient application will vary.

As previously mentioned, a blend is a mix of granules, which, as single granules contain one nutrient at most, makes it virtually impossible to get an even distribution of every granule. This is made even worse when the granule contains more than 50 per cent filler and results in uneven distribution and other stresses caused by under or over application.

Granule size is very important when it comes to applying fertiliser. The size dictates surface suitability. There are many different granule sizes:

Considering granule size only however does not tell the whole story as it is granule size uniformity that is most important when it comes to application. The more uniform the size, the more consistent the application, and therefore the more even response.

One of the problems when surface-spreading very small granules of less than 1mm is that they are easily affected by any slight breeze which will impact upon the accuracy of application.

When applying a fertiliser that has a wide range of granule sizes, application will be affected by what is known as ballistic segregation. This is where the larger, heavier more dense granules travel further from the spinner spreader than the finer, lighter granules.

Where there is a wide variation in granule size, this can mean the outside of the swath might only receive half of the nutrition compared to the middle of the swath.

If a multi-size and shape granule blend (type 2) is being applied, their use in the US has shown the application rate can vary from 50 to 225 per cent of the rate required over the same swath.

In summary, to choose the correct fertiliser, consideration must be given to the benefits of a compound granule versus a blend, which raw materials each contain, the size of the granule, and the conditions under which they are being applied in. Simple really!