Understanding pipe sizing in irrigation systems

Related Articles

Seemingly minor changes in your irrigation system’s pipe diameter can lead to major changes in water coverage, potentially affecting disease on the course, writes Peter Robin.

If you are planning to have some pipes replaced in your irrigation system, what do you do? How can you figure out what sized pipes you should install?

Here’s a scenario: the greenkeeper knows that the existing pipe going down the 10th fairway is old two inch diameter PVC, so it makes sense to install a new two inches equivalent pipe … doesn’t it?

Well, not necessarily, and here’s why: Pipes have rough internal surfaces, which ‘burn’ the water pressure via friction (this is called ‘head-loss’). Head-loss in pipes is related to how fast the water travels through those pipes. The faster the water travels, the more pressure is lost through friction. The smaller the pipe diameter, the faster the water must travel to get through to the other end, so smaller diameter pipes ‘burn up’ more pressure than bigger pipes, and so there is less pressure left over for your sprinklers to use at the other end. Conversely, a bigger pipe diameter allows the water to travel slower, so it ‘burns’ less pressure and so there is more pressure left over.

‘So what?’ I hear you ask. Well many golf course irrigation systems suffer from inadequate water pressure. Pressure is the amount of energy in your water (provided by your pump); it provides the force to throw the sprinklers’ water across to the other side of the green (or tee). Poor water pressure will lead to poor water coverage, resulting potentially in dry patch, wet areas, non-uniform playability, possibly weed and moss growth and so on.

Here’s another point to consider. An increase in pipe diameter from, say, 63mm (that is black PE pipe) to 75mm diameter doesn’t sound like much of a jump but this 20 per cent increase in diameter will increase the cross sectional area by 45 per cent, in other words the difference is not linear. This means that a small increase in pipe diameter will make a large difference in how much volume the pipe can hold, and therefore a massive difference in slowing the water down.

Rain Bird golf sprinkler operating at excellent pressure capacity.

So, getting back to the stretch of replacement pipe on the 10th fairway. Firstly, forget about what the existing pipe size is. Instead, we need to know what its flow rate requirement will be. If its purpose is to feed the 10th green with five sprinklers to irrigate all at once, the pipe needs to be big enough to be able to transport the water with a minimal loss of pressure within your budgetary constraints.

So if each sprinkler has a 75 litre per minute nozzle, then the overall flow rate to the green will be 75 x 5 = 375 litres per minute; or 22.5 cubic metres per hour. You can get this info from the internet relating to your sprinklers and their existing nozzles.

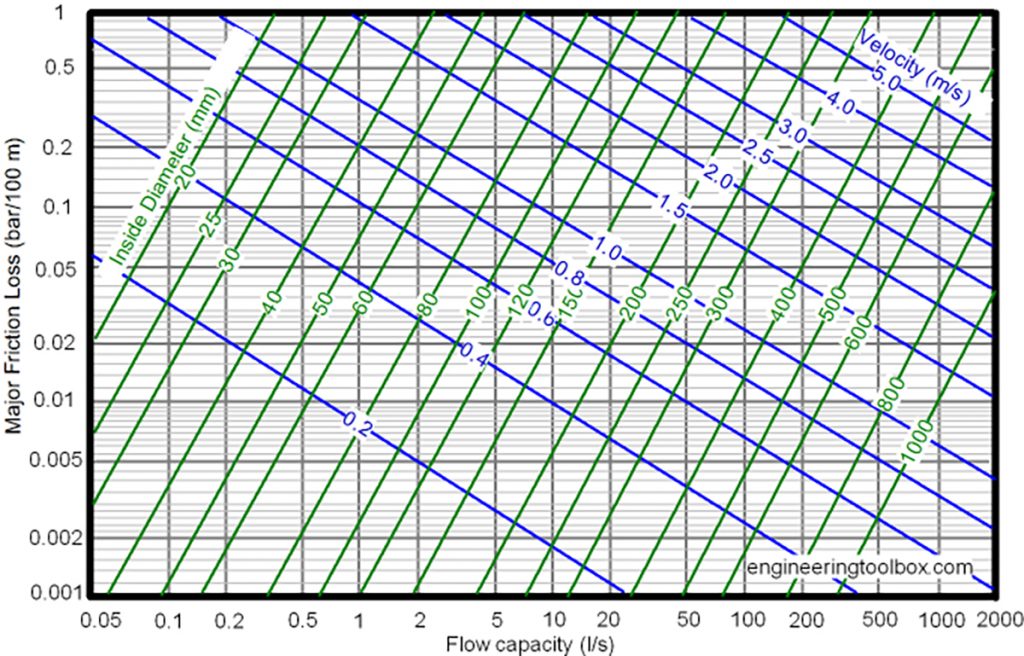

If you use 63mm OD (two inches ID) pipe then the head-loss will be approximately 18 metres per 100 metres of pipe, and the velocity (speed) of the water traveling through it will be around three metres per second. This information is gained from a head-loss calculator. Incidentally, 10 metres in pressure-talk is the same as one bar, so that means you’ll have potentially lost 1.8 bar of pressure over that 100 metres of mainline pipe down your 10th fairway if you stick with a 63mm (two inches) diameter pipe.

Head-loss calculator chart.

If instead you install 90mm OD (three inches ID) pipe, then the head-loss will be just under two metres per 100 metres of pipe, and the velocity will be around 1.2 metres per second. So now you’ll have lost just 0.2 bar of pressure down the same length of mainline.

This is a huge difference! We’ve gone from losing 1.8 bar of pressure over the 100 metres to now losing just 0.2 bar, just by using the bigger diameter pipe. If you started with five bar going into the new pipe, you’ll have 3.2 bar at the end of it if you use 63mm pipe, but you’ll have 4.8 bar at the end of it if you use 90mm pipe instead. Imagine the difference if you change more of the irrigation system to bigger pipes.

What happens in the real world is that the sprinklers will just use less water at lower pressures, so the system can even itself out to a certain extent, but to the detriment of the sprinkler’s coverage; at lower pressures and flow rates the sprinklers will perform poorly. Uniformity will suffer and you’ll get serious problems, including an ongoing problem with severe dry patch – every greenkeeper’s worst nightmare.

Dry patch potentially cased by poor water coverage.

A good irrigation contractor will be able to work out the best pipe diameters for your specific situation. If they simply suggest you replace like-for-like, feel free to question it. There are two references they should be able to provide you: (1) the velocity of the water through the pipe and (2) the head-loss (pressure-loss) of the new pipe. They should also be able to tell you what the same figures would be if you go up a diameter, which will give you the comparison you need.

Some professionals aim at a velocity of 1.5 metres per second maximum. This is the speed that the water will be traveling through your new pipe.

I personally prefer a lower velocity of around one metre per second; this lower velocity will save a huge amount of pressure because, as we have discussed, the water will be traveling slower. The bigger diameter pipe will be more expensive though, and this is why many contractors, worried about being competitive, will quote a smaller diameter pipe.

Head-loss, the other point of reference, is massively affected by pipe diameter, as previously described in the 10th fairway example. Your contractor should be able to show you the head-loss figure for each diameter pipe.

So next time you’re thinking of installing any new pipe, be it in a new stretch or replacing an existing pipeline, make sure you ask the right questions and get some definitive answers. You are welcome to contact me if you’d like a second opinion: peter.robin@rigbytaylor.com

Peter Robin

Peter Robin is the UK irrigation product manager at Rigby Taylor. For more information, visit www.rigbytaylor.com