These golf course mowers are aimed at maximising plant health

Related Articles

Ever-tightening controls on pesticides and chemical usage means mowing now has to be much more than simply cutting the grass – it has to be effective in turf conditioning itself. Here leading manufacturers highlight to Andy Waple the equipment that’s aimed at maximising plant health.

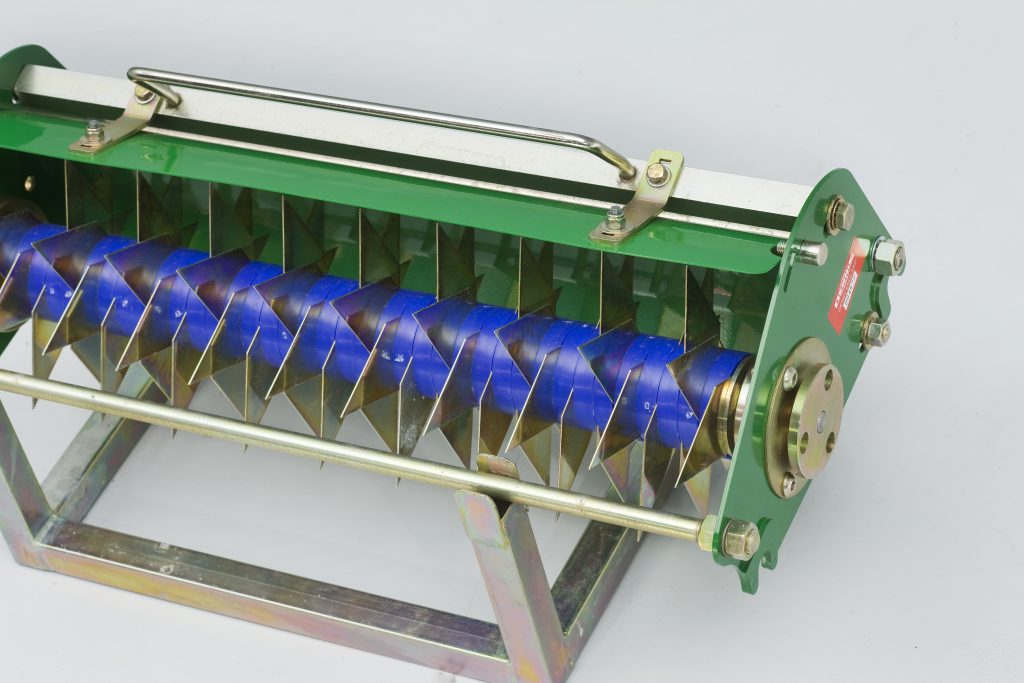

With changes in pesticide legislation having an ever-deepening effect on sports turf quality, turf managers are having to carefully consider the role of mechanical maintenance in delivering a proactive plant health strategy. The UltraGroomer™ cassette from the renowned TMSystem™ collection from MTD is specifically designed to provide a healthier turf environment by preventing the accumulation of thatch.

A thatchy surface that is moisture retentive not only reduces the movement of oxygen and nutrients, it also provides an ideal environment to harbour pathogens. The UltraGroomer™ cassette features over 80 tungsten carbide tipped blades, spaced at 5mm apart, to reduce poa ingress, minimise puffiness and prevent the build-up of organic matter. By improving the plant’s immediate environment, it becomes more difficult for disease pathogens to take hold.

The UltraGroomer™ can also be effectively used in conjunction with other cassettes from the TMSystem™ range, particularly the SMARTVibe™ to increase greens’ speed. During the winter months, when the plant is at its most vulnerable, the SMARTVibe™ can be employed as an alternative to mowing to reduce plant stress. Vibratory rolling can smooth the greens surface and quicken play without cutting, eliminating passes of heavy pieces of equipment which, in turn, lowers the risk of compaction.

The TMSystem™ is available to fit OEM triplex and light fairway machines, as well as being an integral part of the Cub Cadet INFINICUT® mower. Also playing its part in the fight against disease, the INFINICUT® range features a number of parameters that can be adjusted to deliver an unparalleled quality of cut, no matter the time of year or conditions encountered at the given time. The INFINICUT® cylinder mower range spans 22”/26”/30” and 34” working widths, and floating or fixed head variants, together with the recently launched SM34 Rotary Mower.

Thirty years after its launch, the classic Toro Greensmaster 1000, beloved by so many across the globe, has had a redesign.

The range comprises the Greensmaster 1018, Greensmaster 1021 and the latest, the Greensmaster 1026, which launched this year, brings with it the widest cut yet.

Revamping brings operator and greensmower into perfect harmony thanks to multiple innovations – starting with an industry-first telescoping handle – which come together to deliver unparalleled quality of cut and consistent playability on each and every green in this series.

In fact, all that remains the same are the patented DPA cutting units, but even that has had a modular redesign to allow the driveline and chassis to be removable for eased servicing, saving time and money and lowering the total cost of ownership.

Jeff Anguige, national sales manager at Reesink, sole Toro distributor in the UK for golf and sports fields equipment and irrigation products, says: “This series redesign clearly demonstrates what Toro does best – it takes something beloved by many and widely believed to be great just as it is and makes it even better. Delivering more of what we expect as technology advances – increased productivity, improved results and a better working experience. It will undoubtedly become the new legend in greensmowing.

“This range of pedestrian mowers brings consistency to fixed-head pedestrian greens mowing. With the innovative telescoping handle, each machine can accommodate operators of different heights and skill levels and now with the Greensmaster 1026, this can deliver the widest cut yet at 26 inches.”

Additional benefits that come with the range include a heavy-duty 3.5hp Honda engine and a choice of cutting units. Increased productivity comes in the form of an operational bail for slowing down or stopping in tight turns without disengaging traction and there’s no greasing requirement for labour-saving maintenance. The rubber-mounted handle reduces the oscillation from walking for cutting consistency and delivers further improved results, while the easy conversion capability from greens to tees mowing, balance for tracking and problem-free turn around, and squeeze brake for enhanced control all combine for a better working experience for the operator. And in the case of the Greensmaster 1026, having a wider mowing swath delivers increased productivity.

John Deere greens’ and tees’ mowers are designed to help greenkeepers increase productivity, cut fuel consumption and save time, so they can do their mowing jobs quickly and move on to other essential jobs.

Quick Adjust cutting units, featuring the Speed Link system for extremely quick height of cut adjustment, effectively allow the reels on an entire fleet to be set in the time it previously took to adjust the height of cut on just one mower.

In addition, the E-Cut hybrid mower design, using electric drive for the cutting cylinders, helps prevent oil leaks and spillages; and as the mower runs at less than half of the normal revs, it’s not only quieter, but also provides big savings on fuel.

“There’s a great deal of flexibility in the range,” says John Deere’s turf division sales manager Brian D’Arcy.

“Customers often find advantages in using our greens’ mower for tees and surrounds, for example, rather than a utility mower, as it’s more manoeuvrable and gives a better quality finish.

“Many also use the three-wheel 8000E hybrid fairway mower for cutting the tees and surrounds, as it gives a wider cut and the floating cylinders tackle undulations better.”

The password-protected TechControl display on John Deere’s latest A Model mowers enables the course manager to quickly set or change mowing, turning and transport speeds, for example, to limit variations in performance by different operators and provide a more consistent, quality finish. On-board visual diagnostics and the ability to set regular service times also help to maximise productive time.

With their rugged tubular steel frames, low profile tyres and a wide footprint, John Deere ride-on greens’ mowers are also designed to go easy on precious turf. The tyres are located well inside the cutting units to reduce or eliminate double rolling during straight-line passes.

In addition, the triplex cutting cylinders are offset to the left to help reduce tracking on greens, caused by regular mowing; this is done by changing the direction of travel on alternate days.

During the perimeter cut, the tyres roll across one area of the green one day, and a different area the next, enabling it to recover between cuts. The Quick Tach cutting units also float independently to follow ground contours.

Q&A

Professional mower performance depends on the correct set-up and adjustment procedures. Accurate height of cut tools including a setting bar and proper instructions are essential for setting up a cutting unit.

Here, Robert Jack from Dennis, answers some of his most frequently asked questions.

Why is a sharp, clean cut so important?

Playability and presentation. Cutting or tearing with a blunt cylinder will result in bruising the grass leaf leading to the tip turning white. Not a pretty sight and open to disease.

Why is this poor cut happening?

Either a poorly set mower or wear in the cylinder / bottom blade or cylinder bearing failure.

Why is height of cut important?

Setting the height of cut is critical, particularly on the greens. If the grass is too long then the accuracy and the speed of the ball is affected.

How do I set height of cut?

This is generally done using a height setting bar. There is a threaded bolt with a locking nut that goes through the setting bar and the desired mowing height is measured from the top of the bar to the underside of the bolt head. On a pedestrian mower the bar is placed under the two rollers with the mower tipped back.

The underside of the bolt head is placed on the top of the bottom blade. The mowing height is adjusted by raising and lowering the front roller as the rear roller is fixed. When the front roller rests on the top of the setting bar the roller can be locked in position.

Both sides must be set to be certain of the same height of cut across the full working width.

Why do greenkeepers use cassette system cylinder mowers?

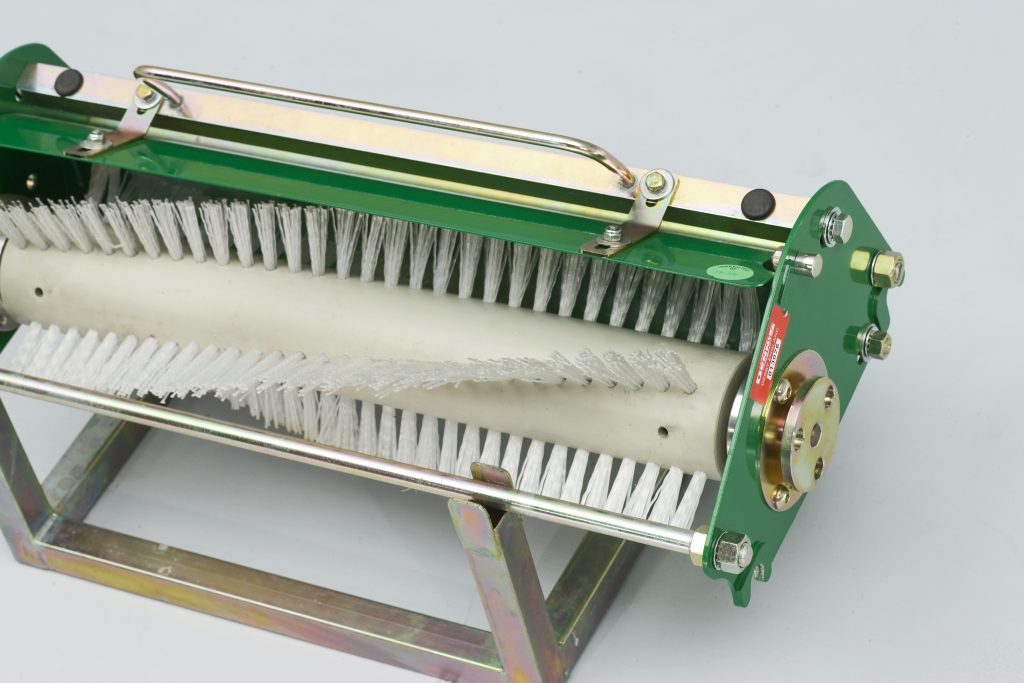

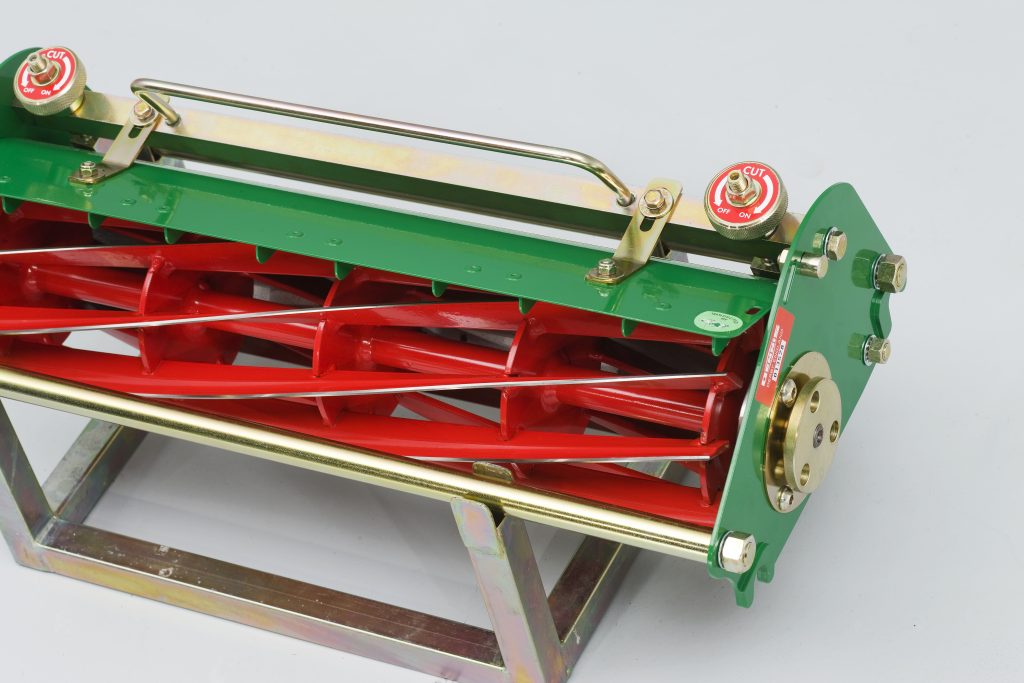

Cassette systems offer flexibility and a single power unit solution for many day-to-day maintenance tasks such as scarifying, verticutting and brushing. Additional cassettes can be purchased to enhance the system and also cassette machines reduce the maintenance costs because there is only one engine and drive system to service. The system also takes up less space in the shed.

Does the number of blades on a cylinder affect the quality of cut?

Generally speaking the more blades in the cylinder, the finer the cut will be.

Other factors need to be considered such as the diameter of the cylinder and the speed of rotation.

When selecting a cylinder, frequency of mowing must be a major factor as the more blades in a cylinder the less grass taken off on each cut.