How to remove algae, mould, lichens and moss from the golf course

Related Articles

Winter is the perfect time for areas of the course to become covered in algae, mould, lichens and moss. However, there is now an acid that greenkeepers can use, that works very quickly, even under poor conditions, to rid the course of this unsightly greenery, reports Rigby Taylor.

Greenkeepers spend a huge amount of time looking after and keeping greens green. At this time of year however other areas also have a tendency to turn that colour!

With damp cool conditions, reduced footfall and low light levels these areas become covered in algae, moulds, lichens and moss. As a result these areas become very green, unsightly, sometimes hazardous and provide a poor impression of the facility.

To keep staff and golfers safe on these hard surface areas this unwanted greenery needs to be de-greened to reduce the risk of:

- Slips and falls

- Areas freezing and becoming very slippery

- Damage to surfaces by invasive species due to water ingress

- Areas looking unkept with invasion of the green simple organism including moss.

Products designed to control simple organisms such as algae, moulds and so on are classified by HSE as biocides. This group of products consist of a range of different active ingredients mixed with co-formulants to produce formulated branded products. There is a huge range of formulated products registered by HSE under COPR (Control of Pesticides Regulations) as biocides. However, the number of active ingredients is limited. The regulations are further complicated by:

- New Registrations for biocides now having to be submitted under EU Biocidal Product Regulations 528/2012 (EU BPR) – this is a full assessment of the safety of the components of the product using the latest biological and environmental assessments. This work has taken the EU authorities a huge amount of time. Under Brexit we will follow the same regulatory pathway.

- If companies claim their products are surface cleaners rather than biocides. These products are controlled by the detergent regulation – (EC) No 648/2004 which are less stringent and relevant to use on hard surfaces.

- Greenkeepers should be using HSE professionally registered products for degreening hard surfaces. These products will all have either an HSE number or a UK BP number on the label of the product. Clubs and users can then be assured the products are safe to use when label recommendations are followed.

Most de-greener biocides are based on a number of Quaternary Ammonium Compounds (QACs) and are still registered under the COPRA UK regulations. They have not yet received BPR approval in the EU. Examples of these types of products are Qualgex Pro, Safor, MMC Pro, Algolite and many more.

These are surface-active substances containing a quaternary cationic nitrogen atom, substituted by alkyl chains of varying length. They are used as biocides, pesticides, disinfectants and additives for technical applications.

- BAC is a mixture of alkylbenzyldimethylammonium chlorides of various even-numbered alkyl chain lengths (C8-C18). The greatest biocide activity is associated with the C12-C14 derivatives, which are the main components of the mixture.

- DDAC is a mixture of alkyl-quaternary ammonium salts with typical alkyl chain lengths of C8, C10 and C12. C10 is the main component and makes more than 90 percent of the mixture. In most cases the term DDAC is thus used for the Didecyldimethylammonium chloride congener.

With the large number of product brands users need to carefully check the concentration of the active ingredients in the formulations, these vary from 4.8 up to 40 percent.

The literature and label recommendations for use are often not very clear often they make claims which are different to the label recommendations and the registered dose and application area per pack.

The registration can be checked on the HSE Biocide database.

QAC containing products all need similar conditions to perform effectively. They all need large volumes of formulated product circa 100 to 200 litres of product. This needs to be applied in about 1,000 to 2,000 litres of spray per Ha. Hence a 15l knapsack will only treat about 40-80 square metres of hard surface per fill. These products also require a 24-hour drying cycle post application to work effectively. Also they must not be applied in cold or frosty conditions or when there is danger of rain.

In the past all these products used to have moss on their labels, however under modern registrations, moss is classified as a plant. To control plants you need to have a full Plant Protection Product (PPP) registration for a herbicide. These are very expensive and none of the QAC products have been submitted for inclusion as PPP. The only product registered for use on hard surface for moss control is acetic acid, sold as New-Way Weed Control.

Recently nonanoic acid has received UK BPR approval for use as a hard surface biocide.

Nonanoic acid is a naturally derived ingredient extracted from sunflower and oilseed rape meal. Enclean is a 500 g/l nonanoic acid formulation.

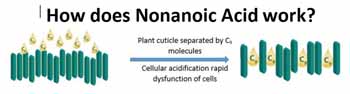

How does nonanoic acid work?

Nonanoic acid (Enclean) is applied at 18.5 l/ha (five to 10 times reduction in concentrate volume compared to QACs). The spray water rate is only 270 l/ha. Hence, one litre of product plus 14 litres of water in 15l knapsack will treat 555 square metres using a 85 degree red even-spray nozzle. This makes application much easier and quicker, saving both time and money.

Untreated wood shed

Nonanoic acid also has the benefit of working very quickly even under poor conditions. The site pictured was sprayed at the end of October in dull damp conditions and the speed of activity from nonanoic acid (Enclean) can be clearly seen.

Enclean treated woodshed 25 days after treatment

De-greening products can be used in many places around golf facilities: Patios, car parks, artificial surfaces, roofs, netting, car parks, paths around buildings, fire exits, fencing, any wooden structures on the course and signage. Used correctly these product can be an invaluable management tools to achieve good looking and safe facilities. Now is an ideal time to start your de-greening programme, contact Rigby Taylor for more information on the latest biocides.

For more information, visit Rigby Taylor at www.rigbytaylor.com.